Grounding and Bonding for Well Pumps and Water Treatment Systems in Missouri

Rural and suburban Missouri homes rely on wells, pressure tanks, and filtration gear to keep water clean. Those systems run on electricity, and they live in damp spaces where shock and corrosion risks are higher. Proper grounding and bonding keeps people safe, protects electronics inside control heads, and helps motors start cleanly. This guide explains the basics in plain language and shows how to bring a well pump and whole house water treatment system up to modern standards without tearing apart finished walls. If you are planning an upgrade, our team can handle design and permits through the Residential Electrician service.

Grounding and bonding in one minute

Grounding provides a low resistance path from your electrical system to the earth. It helps lightning and utility faults dissipate safely and gives your breaker a solid reference point.

Bonding ties all exposed metal parts together so they share the same electrical potential. When everything metal is at the same potential, a person touching two items at once does not become the path for stray current. Grounding is about a path to earth. Bonding is about connecting metallic parts to each other and to the grounding system.

Both jobs matter anywhere water and electricity meet. A well casing, metal piping, pump frames, filter housings, and UV sleeves should be at the same potential and connected back to the grounding electrode system at the service.

The equipment you are bonding

A typical Missouri well and treatment setup includes:

- Submersible or jet pump

- Pump control box and pressure switch

- Pressure tank and gauge

- Metal well casing or a plastic pitless adapter assembly

- Copper, PEX, or PVC house piping

- Whole house sediment filter and carbon filter

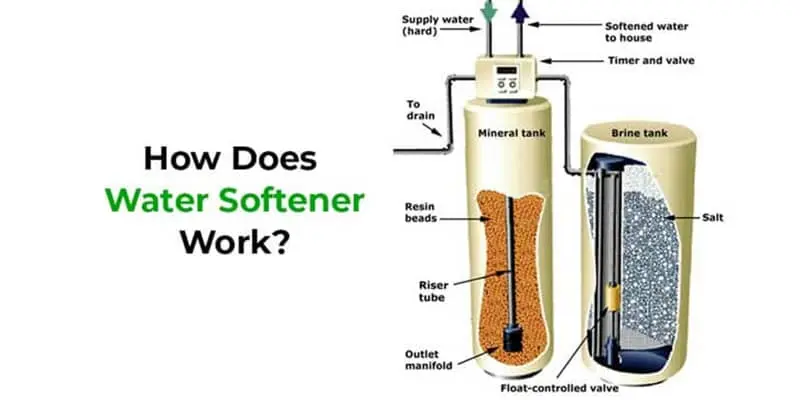

- Water softener with an electronic control head

- UV disinfection unit with an electronic ballast

- Reverse osmosis system or booster pump on some homes

Every metallic part that can become energized by a fault or by induced voltage should be bonded. Every circuit that powers those devices needs an equipment grounding conductor back to the panel.

Safe wiring for pumps and controls

A well pump needs a dedicated branch circuit sized to the motor. Most submersible pumps in Missouri homes are 240 volt and run on a two pole breaker. The cable to the pump includes two insulated conductors and a green or bare equipment grounding conductor. The equipment grounding conductor connects to the metal pump body and frame. Do not leave the pump frame floating. A floating frame can sit at a different potential than the rest of your system and create a shock risk at the well cap or pit.

At the pressure switch and control box, land the equipment grounding conductor on the metal enclosure ground screw. If the pressure switch sits on a metal tee at the pressure tank, bond that metal piping to the grounding system as well.

Inside the house, receptacles that serve water treatment equipment need a grounding connection to the panel. Avoid extension cords for control heads. Use permanent wiring methods and listed strain reliefs at boxes. If the receptacle is in an unfinished basement or utility room, GFCI protection is usually required. If the receptacle is near a sink, GFCI protection is required within typical sink distances. When in doubt, use a quality GFCI device or breaker and label it clearly. For a broader primer on protection devices in wet and finished spaces, see our guide to AFCI vs GFCI in Missouri homes.

The grounding electrode system at the service

Your home’s panel bonds the neutral and connects to grounding electrodes such as ground rods, a concrete encased electrode, and any qualifying metal water piping that is in contact with earth. If your incoming water service is plastic, you will not have a metal water pipe electrode. In that case you still bond interior metal piping to the grounding system so everything metal is at the same potential.

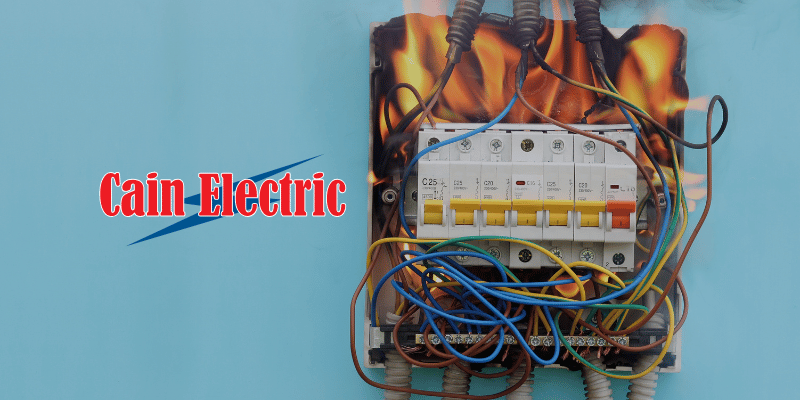

A clean grounding electrode system gives faults a reliable path so breakers clear quickly and so surge protectors work effectively. If your panel is old, the grounding electrode conductor may be undersized or loose. A panel refresh that adds proper grounding and a modern surge protective device often saves appliances and control boards. Review common signs you may need panel work in Signs You Need an Electrical Panel Upgrade.

Bonding the well casing and outdoor equipment

Metal well casings and metal pitless adapters should be bonded to the home’s grounding electrode system. Many older wells were never bonded or the jumper corroded away. Adding a listed bonding clamp to the casing and running a copper bonding conductor back to the service bonding point ties the casing into the same potential as the rest of the home. That reduces shock risk at the well cap and keeps lightning currents on a known path to ground.

Outdoor spigots, hose bibbs, and exposed metal piping near the wellhead should be part of the same bonding network. Use listed clamps and avoid set screws on thin wall pipe. Protect the bonding conductor from weed trimmers and foot traffic. Where a plastic pitless adapter breaks continuity between the casing and house piping, add a bonding jumper that bridges the nonconductive section.

If storms have bent your mast or loosened conduit near the meter, make those repairs before you rely on bonding to do its job. Our Storm Damage Repair team restores mast, meter base, and grounding integrity after wind and ice.

Bonding across plastic sections inside the house

Water treatment gear often includes plastic bypass valves, dielectric unions, and sections of PVC. Those parts make plumbing easier, but they interrupt electrical continuity. Add a bonding jumper around each nonconductive section so the inlet and outlet metal piping share the same potential. Use a short length of copper with listed clamps on each side. Place the jumper where a technician can remove the control head for service without unfastening the bond.

If your entire interior plumbing is PEX or PVC and only short metal nipples exist at the water heater or filter housings, those metal parts still need bonding. Tie them back to the grounding electrode system using a continuous conductor. Label the bond so future plumbers leave it in place.

Grounding for control heads, UV ballasts, and RO pumps

Modern control heads and UV ballasts contain small circuit boards. They are sensitive to surges and to stray voltage that rides on the equipment grounds when bonding is incomplete. Give each device a dedicated grounded receptacle or a clean hardwired connection to a grounded junction box. When a UV system is required for water quality, consider a small uninterruptible power supply or a circuit with surge protection so a brief utility event does not knock the ballast offline.

Some RO systems include a booster pump. Treat that pump like any motor. Provide a grounded receptacle that does not share a loose multi strip. Keep cords out of drip pans. Add a drip loop below the receptacle so water cannot run into the device. If a leak detector shuts off water to the control head, mount the detector and valves so the bonding jumper around plastic sections remains intact when parts are replaced.

GFCI and where to use it

In unfinished basements, crawl spaces, and utility rooms, GFCI protection is commonly required for receptacles that serve water equipment. Pumps can have inrush currents that nuisance trip poor quality devices. Use listed GFCI breakers or receptacles and torque terminations to the manufacturer values. Label the device so technicians know protection is present. If a pump is hardwired on a dedicated circuit, talk to the inspector about the correct protection method before you assume a device is required. When in doubt, our team can help you pick the right combination based on your jurisdiction’s code set in 2025. For a quick refresher on protection in wet areas, see AFCI vs GFCI in Missouri homes.

Surge protection that saves pumps and electronics

Lightning and utility switching events can send short spikes through your service. A whole home surge protective device at the main panel clamps those spikes and protects pump windings, refrigerator boards, softener control heads, and UV ballasts. Add a second surge device at a sub panel that feeds the well equipment if the run is long. For outdoor pumps, keep metal conduit bonded and continuous. Learn how SPDs fit into a home wide plan in Integrating Whole Home Surge Protection and see storm specific tips in Lightning Protection for Solar and Water Equipment.

Plastic plumbing and stray voltage myths

Homeowners sometimes assume plastic plumbing eliminates shock risk because plastic does not conduct. In reality, appliances and pumps are still metallic and connected to circuits. Without bonding jumpers, two metal parts on either side of a plastic section can sit at different potentials. When a person touches both, the person becomes the conductor. Bonding jumpers make those parts equal and safe.

Another myth claims that adding more ground rods near the well cap fixes everything. Ground rods without bonding back to the service can create parallel paths and voltage differences. The safest plan is a single, intentional grounding electrode system at the service with bonding conductors that tie remote metal parts into it.

Common mistakes we fix on well and filtration projects

- No equipment grounding conductor in the cable to the pump

- Floating metal well casing with no bonding jumper to the service

- Filter bypass valves in plastic with no bonding jumpers on inlet and outlet piping

- Control heads plugged into two prong adapters or ungrounded extension cords

- Reversed polarity at a utility room receptacle feeding a control head

- Splices in damp well pits that are not made with listed waterproof kits

- GFCI required but missing, or present but miswired on line and load

- Surge protection missing at a panel that feeds sensitive water electronics

- Metal piping replaced with PEX and bonding never reconnected to the new layout

If you see any of these items, take photos and send them with your address. Our team will map a fix and provide clear pricing before the work starts.

How bonding interacts with solar and generators

Many Missouri well owners add solar or a standby generator. These systems can work together as long as grounding and transfer methods are planned.

With solar, the inverter bonds to the same grounding electrode system as the house. Keep rapid shutdown labels clear and maintain working space at the service. If you plan backup power for the well during outages, a battery and an essential loads panel can feed the pump while the grid is down. See options in Off Grid Solar and Batteries in Missouri and our Solar Services page.

With generators, the transfer switch must prevent objectionable current on the grounding system and must keep the neutral and equipment grounds in their correct relationship. Size the generator for pump starting current so voltage stays stable. Review sizing examples in How to Size a Home Standby Generator and see how solar and generators can work together in Solar and Generator Backup Integration. For generator installs, start here: Whole Home Backup Generators.

Step by step homeowner checklist

- Identify the equipment. List the pump model, control box, pressure switch, pressure tank, filters, softener, UV, and any RO pump.

- Photograph the panel. Note whether a surge device is present and whether spaces are available for a GFCI or dual function breaker.

- Trace the pump circuit. Confirm a dedicated two pole breaker and a cable that includes a green or bare equipment grounding conductor.

- Inspect bonding at the well. Look for a bonding clamp on the casing and a copper conductor running back toward the house.

- Check piping continuity. If you have plastic sections, look for bonding jumpers around them. Add jumpers where metal piping is isolated by plastic.

- Test receptacles. In the utility room and near the pressure tank, test for correct polarity and a working ground. Upgrade to GFCI where required.

- Add surge protection. Install a whole home SPD at the main panel and a secondary device at a sub panel if long runs feed the well equipment.

- Label everything. Label the pump disconnect, pressure switch, and any control head circuit. This speeds inspections and future service.

- Plan for outages. Decide whether a battery or generator will feed the pump. Confirm transfer equipment and bonding stay correct in backup mode.

- Document the layout. Keep photos and notes with your filter maintenance log so future techs can preserve bonding when parts are replaced.

Commercial and agricultural notes

Small businesses, farms, and community systems around Franklin, Warren, and Gasconade Counties often run larger pumps, iron filters, and UV banks. These sites benefit from an equipotential bonding grid in the mechanical room and clear labeling on each skid. Pumps with variable frequency drives need clean grounding and surge protection to avoid nuisance faults. If you are adding treatment capacity or upsizing pumps, speak with our Commercial Electrician team and review demand planning in Commercial Electrical Load Assessment.

When to call an electrician

Call for help if you see tingling when touching plumbing, if a GFCI trips repeatedly, if the pump circuit lacks a green or bare ground, if the well casing has no bonding clamp, or if control heads fail early. Shock symptoms near metal piping are a red flag. A licensed electrician will test for stray voltage, verify continuity of bonding jumpers, tighten terminations to spec, and add surge protection where it matters.

Conclusion

Good water depends on good wiring. When the well casing, pump, metal piping, and treatment gear are all tied into the same grounding system, shocks disappear and electronics live longer. Add surge protection to handle Missouri storms and label the layout so future plumbers keep bonds intact. If you want a straightforward plan, we can evaluate your system, add missing bonds and jumpers, and document everything for future service.

Ready for a quick grounding and bonding check around your well and filtration gear. Tell us your address and share a few photos of the mechanical area, and we will map a clean upgrade path that passes inspection the first time.

Request a well system bonding review

For filtration upgrades and control head replacements, visit our Water Filter page. If you plan to pair the well with solar or a generator, see Solar Services and Whole Home Backup Generators. For seasonal electrical checks around pumps and outdoor receptacles, save our Missouri home seasonal electrical checklist.